There are many types of lighting. When it comes to lighting areas that require special specifications or products, it is important to choose the right option to avoid any future issues. One such area would be freezer lighting applications. A freezer, whether a small unit in a convenience store or a much larger line of units grouped together as one long stretch of freezers, needs specialized lighting that can meet these unique needs. Here are a few helpful tips for choosing the right freezer lighting applications for your location.

- Choose cost efficiency over time instead of initial cost as the deciding factor. For most supermarkets, especially large-scale operations, the freezer units are the biggest energy draws in the location. In fact, it is estimated that some grocery stores have an energy bill where over half of the annual cost of operations is directly related just to the freezer and refrigeration units alone. Look for the lighting solution that will give you the best lumen output per watt of energy consumed for the best value.

- Move away from fluorescent. While fluorescent were once the standard for this area of lighting thanks to their improved efficiency per watt over older options, the new trend is to choose LED for freezer lighting applications. The reason fluorescents are no longer a viable option for this type of lighting need is because they are not designed to handle extreme temperatures well. In fact, they can lose up to 25% of their lighting output in frigid temperatures. LED lights are much better at handling the cold without losing lumen output which makes them a better investment.

- Consider your freezer type. Not all freezers are the units you see at the grocery store in the frozen food section. Freezer lighting can also refer to the much larger freezer found in the backhouse area of restaurants, grocery stores, and other cold storage units. For this area of lighting, you will want to invest in lighting that comes with a cage to protect your bulb. When receiving and organizing deliveries, there will be a risk for accidently hitting the bulb if a delivery is stacked too high. You can avoid this concern altogether with lighting that uses a protective cage design.

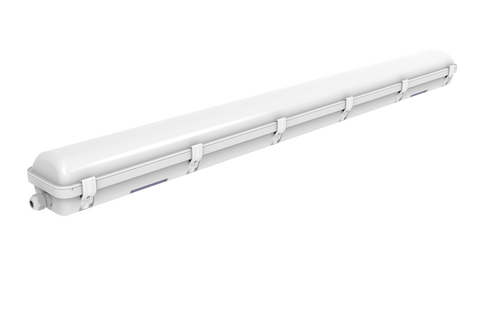

- Make sure lighting is UL listed for wet locations. Freezers can have condensation and vapors that will take a toll on lighting solutions. Another good idea is to choose lighting that is sealed or well-gasketed to avoid internal failures of the solution. In fact, many locations choose to utilize vapor tight options to avoid any issues regarding this type of lighting.

- Don’t forget sensors can save you money. Sensors will shut the light off when the door is not open which will save you money on lighting costs. A god bet is to install multiple sensors per unit to ensure the most savings.

This area of lighting can be expensive for many businesses. With the right lighting solution in place from the beginning, you can avoid costly repairs and replacements while getting a great return on the initial investment of lighting products.

You May Also Be Interested in These Articles...

Cooler Lighting

Lighting can become a costly endeavor for most businesses. For locations including coolers as part of their storage solution, there are a few key elements to finding the perfect option. This is an ...

Read Article

Bar Lighting

From the area behind the bar to where the patrons sit, there are a few aspects to bar lighting. Read on for tips to improve this area!

Read Article

High Bay Vapor Tight T5/T8 Lighting Fixtures

When it comes to finding the right lighting solution, you should first consider if it is an indoor or outdoor area. The area will always determine the lighting solution options. With our h...

Watch Video

Industrial Vapor Tight Lighting Options

When it comes to lighting solutions of incomparable value, one of the best solutions can be found in our industrial vapor tight lighting options. With this type of lighting, you get a powe...

Watch Video High Bay LED Lighting

High Bay LED Lighting

Industrial Low Bay Lighting

Industrial Low Bay Lighting

Industrial Strip Lights

Industrial Strip Lights

Vapor Tight Lighting

Vapor Tight Lighting

LED Shop Lights

LED Shop Lights

Hazardous Area / Explosion Proof Lighting

Hazardous Area / Explosion Proof Lighting

Loading Dock Lights

Loading Dock Lights

Construction / Portable Lighting

Construction / Portable Lighting

Industrial Ceiling Fans

Industrial Ceiling Fans

LED Work Lights

LED Work Lights

Networked Controlled Lighting

Networked Controlled Lighting

NEW Lighting

NEW Lighting

Clearance

Clearance

Troffer Lights

Troffer Lights

LED Flat Panel Lights

LED Flat Panel Lights

Drop Ceiling Lights

Drop Ceiling Lights

Suspended LED Lights

Suspended LED Lights

LED Cylinder Lights

LED Cylinder Lights

Exit / Emergency

Exit / Emergency

Wrap Lighting Fixtures

Wrap Lighting Fixtures

Gooseneck and Barn Lights

Gooseneck and Barn Lights

Stairway & Corridor Lighting

Stairway & Corridor Lighting

Hospital Bed Lights

Hospital Bed Lights

Commercial Sign Lights

Commercial Sign Lights

Recessed Lighting

Recessed Lighting

Wafer Lighting

Wafer Lighting

RGB LED Lights

RGB LED Lights

Grow Lights

Grow Lights

UV Disinfecting Lights & Air Purifier Fixtures

UV Disinfecting Lights & Air Purifier Fixtures

Refrigeration Lighting

Refrigeration Lighting

LED Flood Lights

LED Flood Lights

Outdoor Wall Lights

Outdoor Wall Lights

LED Area Lights

LED Area Lights

Parking Lot Lights & Poles

Parking Lot Lights & Poles

Outdoor Post Top Lights

Outdoor Post Top Lights

LED Stadium Lighting

LED Stadium Lighting

Canopy Lights

Canopy Lights

Security & Motion Sensor Lights

Security & Motion Sensor Lights

LED Bollard Lights

LED Bollard Lights

Outdoor LED Linear Light Fixtures

Outdoor LED Linear Light Fixtures

Solar Powered LED Lighting

Solar Powered LED Lighting

Dusk to Dawn Lights

Dusk to Dawn Lights

Landscape Lighting

Landscape Lighting

Outdoor String Lights

Outdoor String Lights

Coastal Wildlife Lighting

Coastal Wildlife Lighting

Outdoor House Lights

Outdoor House Lights

Architectural Linear Lights

Architectural Linear Lights

Architectural Grid Mount Lights

Architectural Grid Mount Lights

Architectural Round Pendant Lights

Architectural Round Pendant Lights

Architectural Square Linear Lights

Architectural Square Linear Lights

Architectural X-Shaped Linear Lights

Architectural X-Shaped Linear Lights

Architectural LED Wall Packs

Architectural LED Wall Packs

Ceiling Fans

Ceiling Fans

Ceiling Lights

Ceiling Lights

Chandelier Lights

Chandelier Lights

Pendant Lighting

Pendant Lighting

Island Lights

Island Lights

Track Lighting

Track Lighting

Under Cabinet Lighting

Under Cabinet Lighting

Vanity Lights

Vanity Lights

Wall Sconces

Wall Sconces

LED Tape Lights

LED Tape Lights

LED Mirrors

LED Mirrors

LED Light Bulbs

LED Light Bulbs

LED Tube Lights

LED Tube Lights

LED Corn Lights

LED Corn Lights

Vintage LED Bulbs

Vintage LED Bulbs

Decorative LED Bulbs

Decorative LED Bulbs

Fluorescent Light Bulbs

Fluorescent Light Bulbs

Metal Halide Lamps

Metal Halide Lamps

LED Magnetic Strip Retrofit Kits

LED Magnetic Strip Retrofit Kits

LED Strip Light Retrofit Kits

LED Strip Light Retrofit Kits

High Bay LED Retrofit Kits

High Bay LED Retrofit Kits

LED Troffer Retrofit Kits

LED Troffer Retrofit Kits

LED Wall Pack Retrofit

LED Wall Pack Retrofit

LED Street Light Retrofit Kits

LED Street Light Retrofit Kits

Recessed Lighting LED Retrofit Kits

Recessed Lighting LED Retrofit Kits

Ballasts & Drivers

Ballasts & Drivers

Emergency Ballast For LED & Fluorescent Lights

Emergency Ballast For LED & Fluorescent Lights

Electrical Supplies & Mounting Kits

Electrical Supplies & Mounting Kits

Electrical Tools

Electrical Tools

Switches & Receptacles

Switches & Receptacles

Electrical Power Cords

Electrical Power Cords

Sensors and Timers

Sensors and Timers

Smart Home Automation

Smart Home Automation

High Bay Occupancy Sensors

High Bay Occupancy Sensors

Electric Vehicle Chargers

Electric Vehicle Chargers

Hand Dryers

Hand Dryers

LED Shop Lights

LED Shop Lights

Office Lights

Office Lights

Classroom Lights

Classroom Lights

Church Lights

Church Lights

Gym Lighting

Gym Lighting

Factory Lights

Factory Lights

Hospital Lights

Hospital Lights

Walkway Lights

Walkway Lights

Parking Lot Lights

Parking Lot Lights

Exterior Building Lights

Exterior Building Lights

Sports Lighting

Sports Lighting

Airport Lights

Airport Lights

NSF Rated Lights

NSF Rated Lights

Restaurant Lights

Restaurant Lights

Corridor Lights

Corridor Lights

Barn Lighting

Barn Lighting